Oil & Gas Industries

Fueling the World

Oil & Gas Industries Overview

The oil and gas industries are pivotal to the global economy, providing the primary energy sources that fuel transportation, industry, and residential heating.

These industries are divided into three main sectors:

1.Upstream:

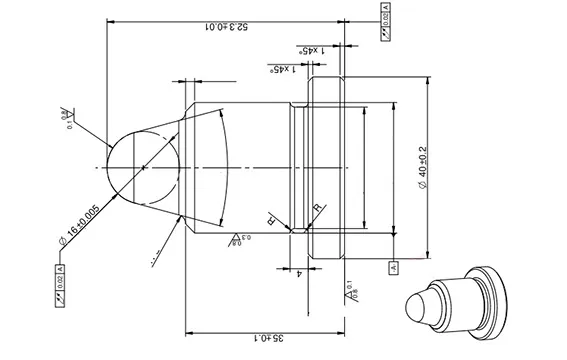

Impellers, shafts, casings, bearings, and seals are examples of pump components that require precision machining to ensure optimal performance. Any deviation in their dimensions can lead to inefficiencies or failures.

2.Midstream:

This sector focuses on the transportation, storage, and wholesale marketing of crude or refined petroleum products. It includes pipelines, tankers, and rail transport.

3.Downstream:

This encompasses refining crude oil, processing natural gas, and marketing and distribution of products derived from crude oil and natural gas. It includes petrochemical plants, refineries, retail outlets, and more.

The Role of Precision Machined Parts in the Oil & Gas Industries

Precision machined parts are indispensable to the oil and gas industries, ensuring the reliability, efficiency, and safety of operations across all sectors.

Here’s how these parts play a critical role:

1.Upstream Applications:

- Drilling Equipment: Precision components such as drill bits, collars, and stabilizers are crucial for drilling operations. These parts must withstand extreme conditions, including high pressure and corrosive environments.

- Wellhead Components: High-precision parts are used in wellhead assemblies, ensuring secure sealing and pressure control to prevent blowouts and leaks.

- Subsea Systems: Underwater exploration and production require components that can endure harsh marine environments, such as control valves and connectors.

2.Midstream Applications:

- Pipelines and Pumps:Precision parts in pumps and valves ensure efficient and safe transportation of oil and gas through pipelines. These components help maintain flow rates and control pressure, minimizing the risk of leaks and ruptures.

- Compression Systems: Precision machined parts are integral to gas compressors, which are used to move natural gas through pipelines. High tolerance and durability are essential to withstand continuous operation.

3.Downstream Applications:

- Refinery Equipment: Refining crude oil into various products involves complex machinery, such as distillation columns and heat exchangers, which rely on precision parts for optimal performance and longevity.

- Petrochemical Manufacturing: Precision components are used in reactors, mixers, and separators to produce chemicals and plastics. These parts must meet exact specifications to ensure product quality and safety.

- Distribution Systems: Valves, regulators, and meters in distribution networks require high-precision machining to accurately control and measure the flow of petroleum products.

Advantages of Our Precision Machined Parts

Our precision machined parts offer several key advantages to the oil and gas industries:

- High Precision and Tolerance: We ensure that every part meets strict tolerance levels, providing reliable performance in critical applications.

- Durability and Strength: Our parts are made from high-grade materials and are designed to withstand extreme pressures, temperatures, and corrosive environments.

- Customization: We offer customized solutions tailored to meet the specific requirements of our clients, ensuring compatibility and efficiency.

- Quality Assurance: Rigorous quality control processes ensure that our parts meet the highest industry standards, reducing downtime and maintenance costs.

By providing top-quality precision machined parts, we play a crucial role in supporting the oil and gas industries’ operations, helping them achieve greater efficiency, safety, and profitability.