Valve Industry

Essential Valves

Valve Industry Overview

The valve industry is critical to various sectors, including oil and gas, water and wastewater management, power generation, chemical processing, and many more. Valves regulate, direct, or control the flow of fluids (gases, liquids, fluidized solids) by opening, closing, or partially obstructing passageways. They come in various types, such as gate valves, globe valves, ball valves, butterfly valves, and check valves, each designed for specific applications and performance criteria.

Role of Precision Machined Parts in the Valve Industry

Precision machined parts are essential to the valve industry, ensuring the valves’ functionality, reliability, and longevity.

Here are key ways these parts play a critical role :

1.Accuracy and Fit:

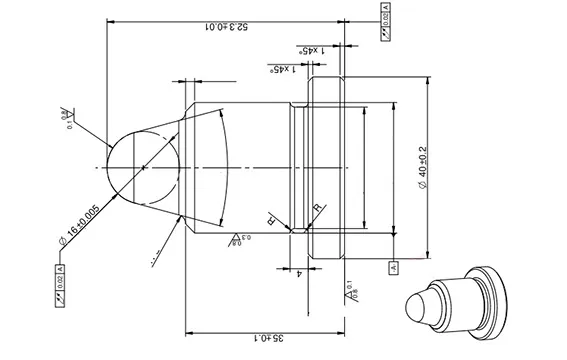

Precision machining ensures that components such as valve bodies, spindles, seats, and disks are manufactured to exact tolerances, which is crucial for the tight seals and smooth operation required in valve systems.

2.Material Compatibility:

Different applications demand materials with specific properties (e.g. , corrosion resistance, high strength, and temperature tolerance). Precision machining allows for the fabrication of parts from various materials, ensuring compatibility with the intended application.

3.Enhanced Performance:

High-quality machined parts minimize wear and tear, reducing the need for maintenance and increasing the operational efficiency of valves. This reliability is vital in industries where downtime can be costly and hazardous.

4.Customization:

Precision machining provides the flexibility to produce custom valve components tailored to specific industry needs, ensuring optimal performance in unique operating conditions.